When it comes to precision machining, choosing the right tools and materials is essential. Solid carbide has emerged as a top choice for milling applications due to its excellent properties, including high hardness, wear resistance, and thermal stability. Vega Tool Corporation, a leading cutting tool manufacturer, has developed a range of solid carbide milling tools that offer outstanding performance and long tool life. In this blog, we will explore the benefits of solid carbide milling tools and why they are the preferred option for modern machining operations.

What is Solid Carbide?

Solid carbide is a type of tungsten carbide material that is sintered under high pressure and temperature. It is a composite of tungsten carbide particles and a metallic binder, usually cobalt. Solid carbide has a unique microstructure, consisting of uniformly dispersed carbide grains within a metallic matrix. This structure gives solid carbide its exceptional mechanical properties, such as high hardness, toughness, and thermal stability.

Solid Carbide Milling Tools: Advantages and Applications

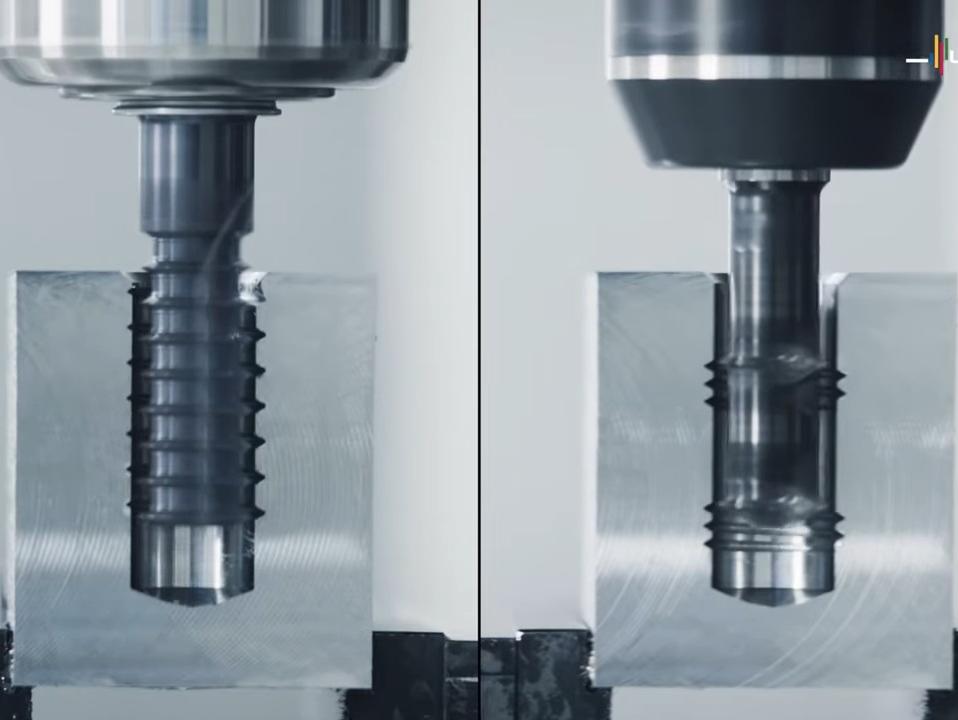

Milling is one of the fundamental machining processes in the manufacturing industry, used to remove material from a workpiece by rotating a cutting tool around its axis. Solid carbide milling tools offer several advantages over other materials, such as high-speed steel (HSS) and cobalt steel (HSCO). Here are some of the benefits of solid carbide milling tools:

1) High Hardness and Wear Resistance: Solid carbide has a high hardness level, typically ranging from 90 to 93 HRA (Rockwell hardness). This makes it ideal for machining hard materials, such as stainless steel, titanium, and hardened steel. Solid carbide also has excellent wear resistance, ensuring consistent machining quality and long tool life.

2) Thermal Stability and Heat Dissipation: Solid carbide has a low coefficient of thermal expansion, which means it can withstand high temperatures without deforming or cracking. The heat generated during the machining process is quickly dissipated through the cutting tool and the chips, preventing tool overheating and workpiece deformation.

3) Accuracy and Precision: Solid carbide milling tools have superior geometries and edge sharpness, ensuring precise cuts and minimal runout. These tools can achieve tight tolerances and smooth surface finishes, making them suitable for high-precision machining operations such as aerospace, medical, and mold making industries.

4) Reduced Tool Changeovers: Due to their exceptional wear resistance, solid carbide tools do not require frequent replacements like HSS or HSCO tools. This reduces downtime and tool changeover costs, improving productivity and efficiency.

At Vega Tool Corporation, we offer a variety of solid carbide milling tools, including end mills, ball nose mills, roughing mills, and slot drills. Our tools are designed with advanced geometries and coatings, providing excellent chip removal and cutting performance. Our new ATH and PN coatings are specially formulated to enhance tool life and productivity, providing maximum efficiency for customers.

Conclusion

In conclusion, solid carbide milling tools are the preferred option for precision machining operations due to their exceptional mechanical properties and performance advantages. Vega Tool Corporation offers a wide range of solid carbide milling tools that cater to the diverse needs of the manufacturing industry. From aerospace to medical to mold making, our products have been trusted by customers worldwide for their reliability and quality. For your next milling application, partner with Vega Tool Corporation and experience the power of solid carbide.